what is impact test in steel|impact test on metal specimen : factories Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its . Bwinners online sportsbook 2024 review from a sports betting expert. Read to learn about Bwinners bonuses and promotions, gambling features, rules, sign-up process, support, .

{plog:ftitle_list}

WEB1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Next. 360p. Depois de Tomar a Vacina Velho Comendo as Novinha. 2 min Rodolfo D Almeida Colmanetti - 360p. Acesse CamPrive.me Para Ver .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .

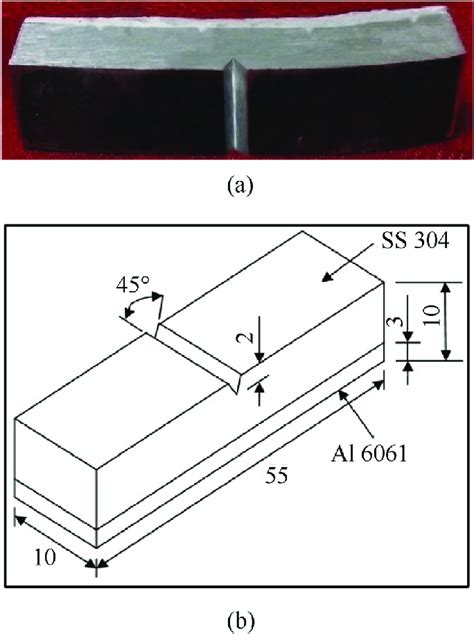

Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or .According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55 mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm × 3.3 mm × 55 mm, 10 mm × 2.5 mm × 55 mm. Details of specimens as per ASTM A370 (Standard Test Method and Definitions for Mechanical Testing of Steel Products).

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, .

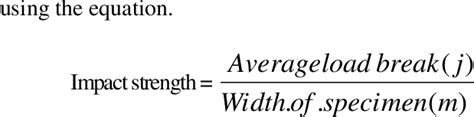

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These characteristics are vital for selecting materials that meet specific application requirements, resulting in safer and more .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.completed impact tensile testing results at -20oF conditions for dual-marked 304/304L and 316/316L stainless steel material specimens (hereafter referred to as 304L and 316L, respectively). Recently completed welded material impact testing at -20 oF, room, 300 oF, and 600 oF is also reported. Utilizing a drop-weight impact test machine and 1/4 .Impact testing is classified according to how a material resists impact. The following are the different types of impact test machines: Charpy Impact Test: The Chapy impact test is a widely used method to determine the toughness of a material. In this test, a pendulum is swung by a weight on the top of a test sample to create an impact.

The test is quite similar to the Charpy impact test, with the exception that the specimen is set up differently. The sample in an Izod impact test is held in a cantilevered beam configuration as opposed to a three-point bending configuration like in a Charpy impact test. Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive (screw thread) somewhere, with the force transmitted to a cross-head and thence via a gripping system to the sample and then to a base .As duplex stainless steels contain both austenitic and ferritic microstructures, their impact toughness is limited by the presence of the ferritic microstructure. The ductile-to-brittle transition temperature is approximately –50°C. Testing Impact Toughness. The most widely used test of impact toughness is the Charpy test.

For example, when impact tests are required as part of the classification of an electrode, they are machined from the same test weld as the tensile specimens. The test plate is 20 mm thick and the impact specimens are located mid-thickness as shown in Figure 4 below. The notch is placed perpendicular to the plate surface on the centreline of .ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .

Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, .Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability .

www.impacttestonline testing

impact test on metal specimen

Tensile Testing is a form of tension testing and is a destructive engineering and materials science test whereby controlled tension is applied to a sample until it fully fails.. This is one of the most common mechanical testing techniques. It is used to find out how strong a material is and also how much it can be stretched before it breaks.

An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a . hi guys, may i need the help regarding to impact test for stainless steel A182 Gr316, the input is code construction ASME B31.3, design temperature is -90 to 100 degree C. so need i do the impact test for PQR during qualification stage.

how to calculate impact strength

1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide assurance all .

charpy impact test sample

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).Predicting Charpy Impact Energy for Heat-Treated Steel using a Quantum-Membership-Function-based Fuzzy Model, Accessed FEB 2019; 2. What is Charpy V-notch Test (CVN Impact test), HYSP, Accessed FEB 2019; 3. Mechanical testing - Notched bar or Impact testing, TWI, Accessed FEB 2019.For example, when testing steel for use in cold climates, the ASTM A370 Charpy impact test can reveal how the material’s toughness decreases as temperatures drop. This information is vital for ensuring that the steel won’t fail under cold conditions, as brittle materials are .

Notched bar or impact testing – Part 1 Before looking at impact testing let us first define what is meant by 'toughness' since the impact test is only one method by which this material property is measured. . In a carbon or low alloy steel the lowest impact values are generally to be found close to the fusion line where grain growth has .

charpy impact test calculations

An alternative test to determine toughness is the Izod impact strength test. Impact strength is such an important mechanical property to know because metals are subjected to collisions and impacts – even if it is unplanned – in so many applications. . mild steel, stainless steel, aluminum, tool steel, alloy steel, brass, bronze and copper .

Get your popcorn ready for these upcoming Brazzers.com vid.

what is impact test in steel|impact test on metal specimen